DIY Ottoman | Make your own Ottoman | Best Foam for Ottoman

Ottomans are an excellent piece of furniture should you be short of storage in the home. Available in a range of designs and made from a vast number of different materials, ottomans are truly customisable. However, it is sometimes tricky to find the perfect option should you have a particular space in mind. For example, for smaller spaces, you may have found an ottoman in the perfect shape and colour, but sadly not in your required size.

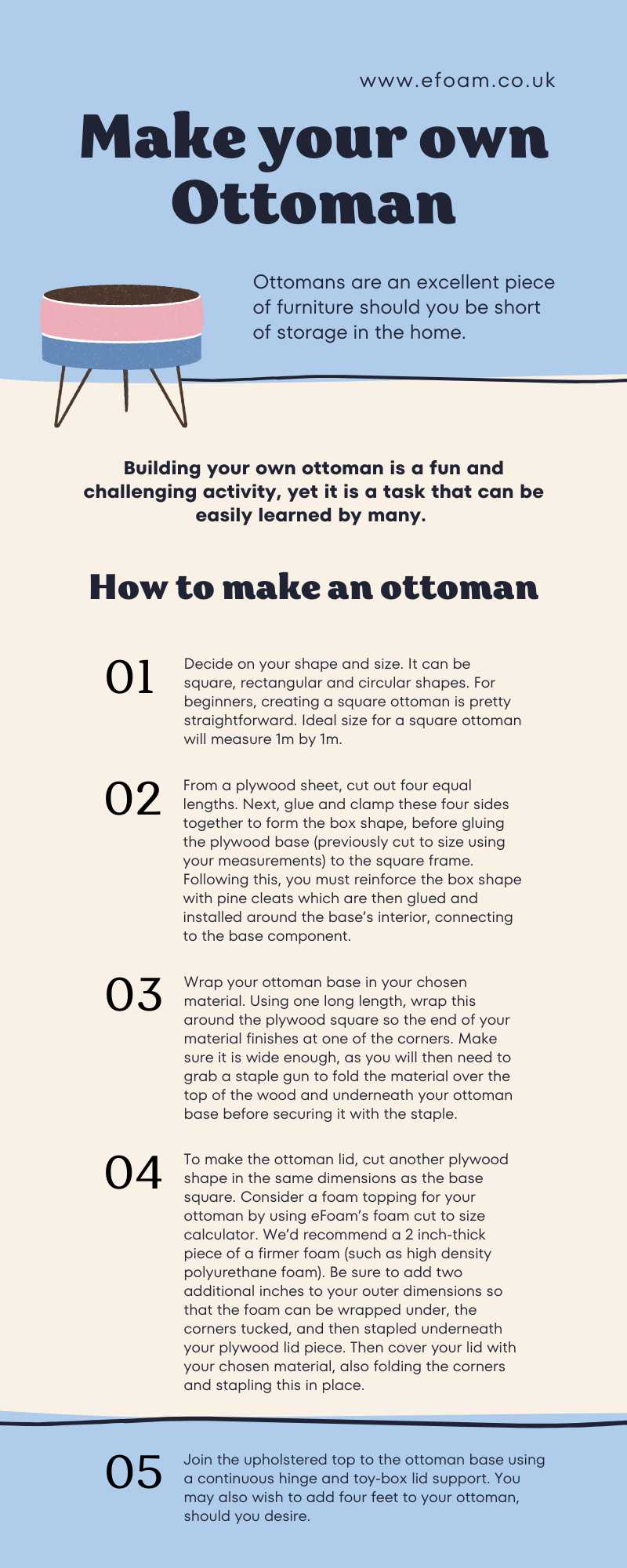

Building your own ottoman is a fun and challenging activity, yet it is a task that can be easily learned by many. Whether you’re an avid DIY-er or a novice, there is plenty of guidance available to those who may be looking to make a custom-designed ottoman. As the COVID-19 lockdown has shown us, we can all turn our hands to DIY ottoman if we try!

Our customer Jason, purchased a piece of foam cut to size and upcycled an old 1950’s ottoman that had been left untouched for a long time. He very kindly sent us a video & photographs of the end result (see top right image).

5 steps to make your own ottoman

Step 1:

The first step to creating your own ottoman is to decide on your shape and size. These can range from square, to rectangular and to circular shapes, although for beginners, creating a square ottoman is likely to be most straightforward. The typical size for an ottoman will measure 1m by 1m, although this can vary depending on your needs.

Step 2:

From a plywood sheet, cut out four equal lengths. Next, glue and clamp these four sides together to form the box shape, before gluing the plywood base (previously cut to size using your measurements) to the square frame. Following this, you must reinforce the box shape with pine cleats which are then glued and installed around the base’s interior, connecting to the base component. Should you wish, it’s also worth reinforcing the corners of the ottoman by using pine blocks inside each corner to support it. Glue these in and clamp where possible.

Step 3:

Next, you will need to wrap your ottoman base in your chosen material. Using one long length, wrap this around the plywood square so the end of your material finishes at one of the corners (it is far easier to hide here). Make sure it is wide enough, as you will then need to grab a staple gun to fold the material over the top of the wood and underneath your ottoman base before securing it with the staple.

Step 4:

To make the ottoman lid, cut another plywood shape in the same dimensions as the base square. At this stage you’ll need to consider a foam topping for your ottoman, and by using eFoam’s foam cut to size calculator, we can cut this to size and shape. We’d recommend a 2 inch-thick piece of a firmer foam such as high density polyurethane as this will resist pressure should you decide to also use this ottoman as a footrest or seat cushion. When ordering your foam pad, be sure to add two additional inches to your outer dimensions so that the foam can be wrapped under, the corners tucked, and then stapled underneath your plywood lid piece. Then cover your lid with your chosen material, also folding the corners and stapling this in place.

Step 5:

After these steps, join the upholstered top to the ottoman base using a continuous hinge and toy-box lid support. You may also wish to add four feet to your ottoman, should you desire.

If you require any further guidance on building your own ottoman, please contact one of our friendly eFoam advisers.